The inner tank is a crucial component of water heaters, responsible for storing and heating water efficiently. The production of high-quality inner tanks is essential to ensure the reliability and longevity of water heaters. In this blog, we delve into the intricacies of water heater inner tank production, explore the benefits of advanced manufacturing processes, and discuss the future trends shaping the industry.

The Importance of Inner Tank Quality

The inner tank plays a pivotal role in the overall performance of a water heater. A high-quality inner tank ensures:

- Durability: Resistant to corrosion and wear, extending the lifespan of the water heater.

- Efficiency: Maintains consistent water temperature, reducing energy consumption.

- Safety: Prevents leaks and withstands high pressure, ensuring safe operation.

Investing in advanced production techniques for inner tanks is essential for manufacturers aiming to deliver reliable and efficient water heaters to their customers.

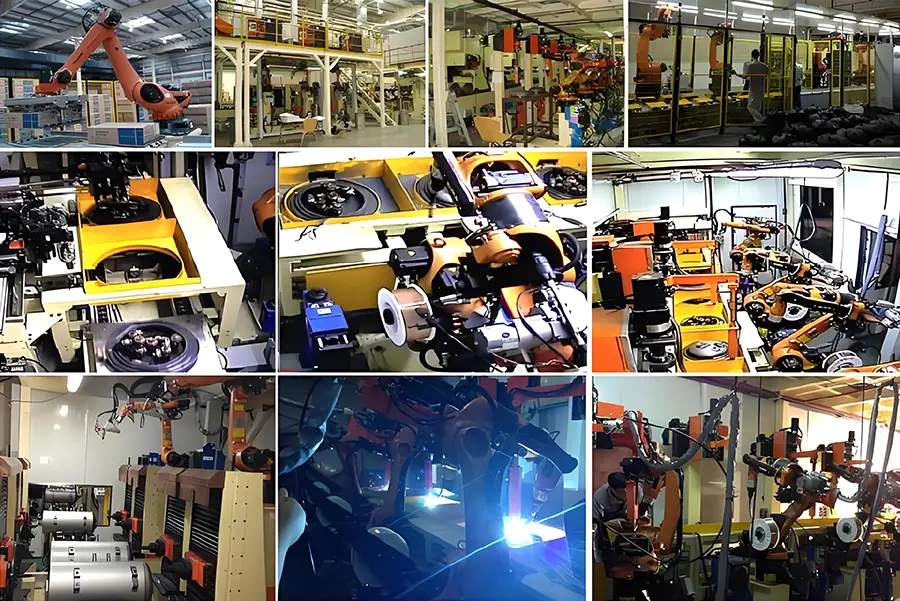

Advanced Production Processes

The production of water heater inner tanks involves several key steps, each requiring precision and expertise. Here are the main stages in the production process:

1. Hydraulic Press

The hydraulic press is used to shape and form the inner tank components by applying high pressure. This step ensures uniform and precise shaping, which is crucial for the overall integrity of the water heater.

2. Punch Press Machine

The punch press machine creates holes and openings in the tank components. These openings are necessary for subsequent assembly and welding, ensuring proper fit and functionality.

3. Hydraulic Rolling Machine

The hydraulic rolling machine rolls the metal sheets into cylindrical shapes, forming the main body of the inner tank. This step provides the basic structure needed for further processing.

4. Shrinking Machine

The shrinking machine reduces the diameter of the tank ends to ensure a tight fit. This ensures secure connections between different tank sections, enhancing the overall durability of the water heater.

5. Automatic Rotary Gun Welding Machine

This machine performs precise welding of the tank’s circular seams. Strong and consistent welds are critical for maintaining the tank’s pressure and preventing leaks.

6. Tank Circular Seam Welding Machine

This machine provides additional welding support to ensure all seams are robust and leak-proof, reinforcing the structural integrity of the tank.

7. Straight Seam Welding Machine

The straight seam welding machine ensures that the long seams of the tank are securely welded, maintaining the structural integrity of the tank.

8. Shot Blasting Machine

The shot blasting machine cleans the tank surfaces by blasting them with abrasive materials, removing impurities, rust, and scale. This prepares the tank for further treatments or coatings.

Benefits of Advanced Production Techniques

Advanced production techniques offer numerous benefits:

- Enhanced Durability: Precision manufacturing ensures the inner tanks can withstand high pressures and resist corrosion, extending their lifespan.

- Improved Efficiency: Consistent and precise shaping and welding result in better heat retention and reduced energy consumption.

- Cost-Effectiveness: Automation and advanced machinery reduce labor costs and minimize material waste, making production more economical.

- Safety: High-quality production reduces the risk of leaks and failures, ensuring the safe operation of water heaters.

Future Trends in Inner Tank Production

The water heater industry is continually evolving, with new trends and technologies emerging. Here are some future trends to watch:

1. Smart Manufacturing

Integration of IoT and AI in manufacturing processes allows for real-time monitoring and optimization, leading to increased efficiency and reduced downtime.

2. Sustainable Practices

Eco-friendly manufacturing techniques, such as using recycled materials and reducing energy consumption, are becoming more prevalent.

3. Advanced Materials

The development of new materials, such as advanced alloys and composites, enhances the durability and efficiency of inner tanks.

4. Customization

Manufacturers are increasingly offering customizable solutions to meet specific customer requirements, providing more tailored and efficient water heating solutions.

The production of water heater inner tanks is a complex and critical process that requires advanced technology and expertise. By investing in state-of-the-art production lines and embracing future trends, manufacturers can deliver high-quality, durable, and efficient water heaters that meet the evolving needs of consumers.

For more information on our water heater inner tank production lines and to discuss your specific requirements, please contact us today. Let’s innovate together for a better and more sustainable future.

Related Articles

- How to choose gas cylinder hydrostatic test equipment for lpg gas tank productio

- Crafting Excellence: Water Heater Production Innovation

- Enhancing Efficiency with Jiuying’s Oil Tank Production Line

- Introducing JY’s Advanced Water Tank Making & Welding Machines

Contact Us

For inquiries, quotes, or further information, please reach out to us:

📞 Phone/Wechat/Whatsapp: +86-13394110095

📧 Email: liu@weldcnc.com

🌐 Website: https://www.toproductline.com/

Stay updated with our latest news and innovations by subscribing to our newsletter!