Welcome to the blog of JY, where we offer cutting-edge solutions for steel door manufacturing. In this post, we will delve into our advanced steel door production line, exploring its working principles, unique features, and diverse applications. We aim to provide you with a comprehensive understanding of how our production line can enhance your operations and help you stay ahead in the competitive market.

How Our Steel Door Production Line Works

At JY, our steel door production line is meticulously designed to ensure a smooth and efficient manufacturing process. Here’s an in-depth look at the production sequence, divided into two primary sections: Door Production and Door Frame Production. Each step is essential for creating high-quality steel doors and frames.

1. Door Production

1. Cutting

- Shearing Machine: This machine cuts large steel coils or sheets into smaller, manageable sizes required for door panels. The precision of the shearing machine ensures uniformity in panel dimensions, which is critical for the consistency of the final product.

2. Flattening

- Sheet Flattening Machine: After cutting, the steel sheets may have slight warping or uneven surfaces. The sheet flattening machine smooths out these irregularities, preparing the sheets for the next stages of production. This ensures that the surface is flat and smooth for embossing and punching.

3. Embossing

- Embossing Machine: This step involves creating textured patterns or decorative elements on the surface of the steel sheets. The embossing machine uses pressure to imprint designs or textures, which not only enhances the aesthetic appeal but also strengthens the door surface.

4. Punching

- Combination Punch Machine: This machine performs multiple punching operations simultaneously, creating holes for locks, hinges, and other hardware components. It ensures precise and consistent placement of holes, which is essential for the proper functioning and installation of the doors.

5. Bending

- Bending Machine: After punching, the steel sheets are bent into the desired shapes, forming the edges and contours of the door panels. The bending machine applies controlled pressure to shape the panels accurately according to design specifications.

6. Foaming and Laminating

- Foam Laminating Machine: This machine applies a foam layer to the inner surface of the door panels. The foam serves as an insulating material that enhances thermal and acoustic insulation. It also contributes to the structural integrity of the door.

7. Transfer Printing

- Transfer Printing Machine: The final step in door production involves applying decorative patterns, colors, or finishes to the surface of the door panels. This machine transfers pre-designed patterns or colors onto the door panels, giving them a polished and attractive appearance.

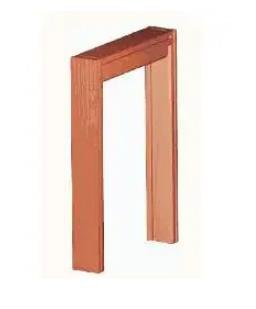

2. Door Frame Production

1. Cutting

- Shearing Machine: Similar to the door panel process, the shearing machine cuts steel sheets into the appropriate lengths and sizes needed for door frames. Accurate cutting ensures that all frame components fit together correctly.

2. Flattening

- Sheet Flattening Machine: Steel sheets used for frames are also flattened to ensure a smooth surface. This step is crucial for avoiding any imperfections that might affect the assembly and alignment of the frame.

3. Punching

- Punching Machines: These machines create precise holes and cutouts in the steel sheets for assembling the frame components. Punching is essential for accommodating hardware such as hinges and lock mechanisms.

4. Embossing

- Door Frame Embossing Machine: Decorative patterns and textures are applied to the frame sections using this machine. Embossing adds visual appeal and can also reinforce the structural strength of the frame.

5. Molding

- Door Frame Molding Machine: This machine shapes the flattened and punched steel sheets into the final frame profile. It ensures that the frame has the correct dimensions and fit, ready for assembly with door panels.

6. Combination Punching

- Combination Punch Machine: This versatile machine performs multiple punching tasks in one go, streamlining the production process and increasing efficiency. It is used to create various holes and cutouts required for frame assembly.

7. Pressing

- Hot Press Machine: In the final stage of frame production, the hot press machine applies heat and pressure to bond frame components together. This step ensures that the frame is strong, durable, and ready for installation.

Key Features of Our Steel Door Production Line

- Advanced Technology: Our production line incorporates state-of-the-art technology, ensuring high precision and efficiency in every stage of the manufacturing process.

- Comprehensive Equipment: We provide a complete suite of machines, including shearing, punching, bending, welding, and coating equipment, offering a fully integrated solution.

- Customizable Solutions: We understand that each production requirement is unique. Therefore, we offer customizable options to tailor the production line to your specific needs.

- Durability and Reliability: Designed with high-quality materials and rigorous testing, our equipment ensures long-lasting performance and reliability.

- Energy Efficiency: Our production line is engineered to be energy-efficient, helping you reduce operational costs and minimize environmental impact.

Applications of Our Steel Door Production Line

Our steel door production line is versatile and can be used in various applications, including:

- Residential Buildings: High-security steel doors for homes, apartments, and condos.

- Commercial Properties: Durable and aesthetically pleasing doors for office buildings, retail spaces, and industrial facilities.

- Public Infrastructure: Robust doors for schools, hospitals, and government buildings, where security and durability are paramount.

Why Choose JY’s Steel Door Production Line?

At JY, we are committed to providing top-notch equipment that meets the highest industry standards. Our steel door production line is designed to enhance efficiency, reduce costs, and improve product quality. By choosing our solution, you invest in a reliable and advanced system that supports your business growth and competitiveness.

Ready to transform your steel door manufacturing process? Contact us today to learn more about our steel door production line and receive a personalized quote. Our team is here to assist you with any questions and guide you through the next steps.

Send us an inquiry now and take the first step toward optimizing your production line with JY!

📞 Phone/Wechat/Whatsapp: +86-13394110095

📧 Email: liu@weldcnc.com

🌐 Website: https://www.toproductline.com/