Qinhuangdao, Hebei Province, is now home to the world’s first dual-process production line. This line can simultaneously produce both straight seam and spiral welded pipes. It addresses the growing demand for new energy transmission pipelines. Additionally, it marks a significant breakthrough in China’s welded pipe manufacturing technology. The 18.3-meter dual-process welded pipe production line uses advanced JCOE technology. This allows it to meet the needs of both the new energy sector and traditional oil and gas transmission markets. As a result, it represents a major step forward in the pipeline manufacturing industry.

JCOE Technology and Production Line Advantages

JCOE technology is essential for producing large-diameter straight seam double-sided submerged arc welded pipes. Compared to traditional methods, JCOE offers a more cost-effective and efficient solution for pipeline manufacturing. The JCOE process uses a step-by-step stamping technique. This significantly reduces equipment costs. In fact, the cost of a JCOE production line is only one-eighth of a traditional UOE line. However, it still achieves 50% of the output. JCOE technology is flexible and allows for the production of pipes with diameters ranging from Φ406 to Φ1829 mm (16″-72″). The length of the pipes can reach up to 18.3 meters, with easy adjustments for different pipe sizes. This flexibility makes JCOE highly adaptable to various project needs.

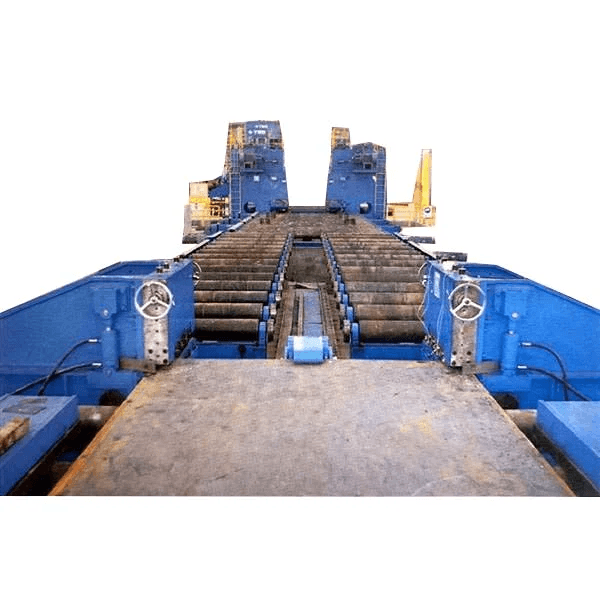

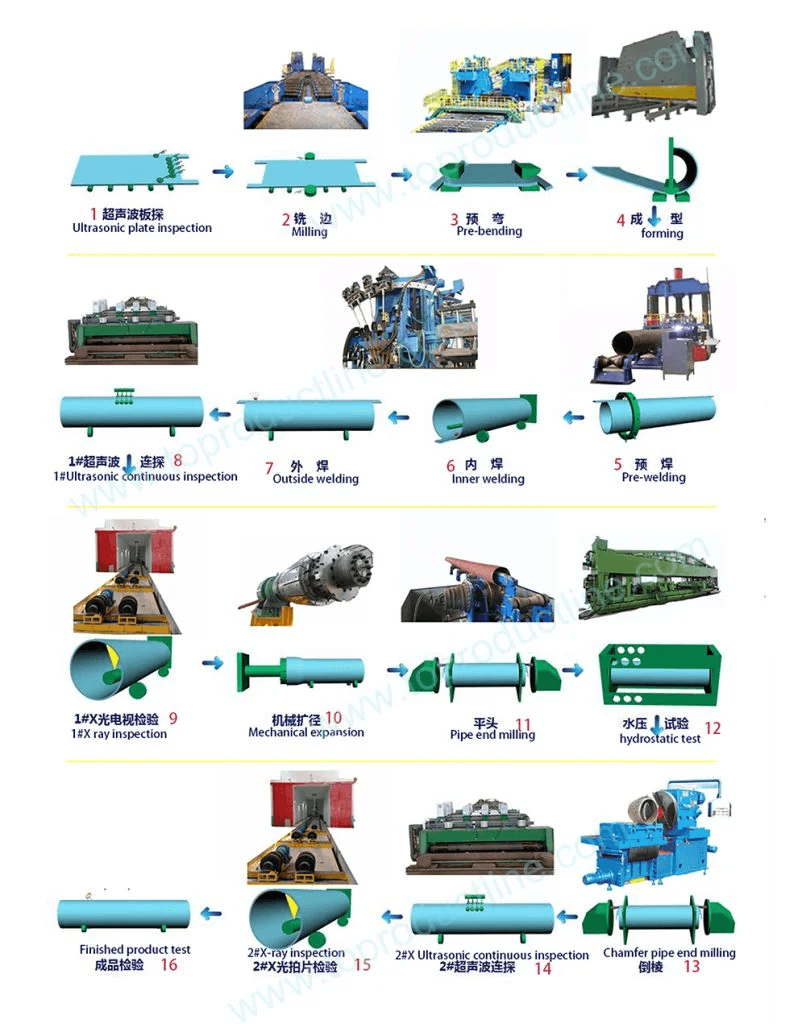

The JCOE production line is equipped with key machinery. This ensures high-quality results throughout the manufacturing process. The edge milling machine mills the steel plates to the required width and bevel shape. The pre-bending machine then gives the plates the necessary curvature. The entire system is controlled by PID technology. This ensures continuous forming with high speed and uniform stress distribution. As a result, the system maintains a consistent pipe shape. This combination of features ensures the production of high-quality welded pipes.

Quality Assurance, Applications, and Future of JCOE Technology

The JCOE production line integrates a comprehensive quality control system. This includes ultrasonic testing, X-ray inspection, and hydrostatic testing. These tests ensure that the pipes meet both domestic and international standards. As a result, the steel pipes produced are reliable and durable. These pipes are used in industries such as water supply, petrochemical, chemical, and power. They are also used in large infrastructure projects like bridges, docks, and piling. Additionally, JCOE pipes are increasingly used for the transportation of new energy sources, such as hydrogen and carbon dioxide. These energy sources are crucial for the development of global energy infrastructure.

As the demand for new energy transmission continues to rise, JCOE technology will play a more crucial role. Its precision, cost-effectiveness, and flexibility make it ideal for meeting the needs of both traditional and new energy projects. Furthermore, advancements in JCOE production technology will continue to support future energy infrastructure. As a result, JCOE steel pipes will remain a key solution in the evolving energy landscape.