Selecting the right wheelbarrow pipe bending machine is essential for ensuring high-quality production and efficient operations in manufacturing. This blog will guide you through the key factors to consider when choosing the best pipe bending machine for your wheelbarrow production needs.

1. Understanding Your Requirements

Before purchasing a pipe bending machine, it’s crucial to understand your specific requirements:

- Production Volume: Estimate your production needs to select a machine that can handle the desired volume efficiently.

- Pipe Specifications: Determine the types, sizes, and thicknesses of pipes you will be bending.

- Bending Precision: Consider the required precision and complexity of the bends for your wheelbarrow frames.

2. Machine Types

There are different types of pipe bending machines available, each with its own advantages:

- Manual Pipe Bending Machines: Ideal for low-volume production or simple bends. They are cost-effective but require more manual effort.

- Hydraulic Pipe Bending Machines: Suitable for medium to high-volume production, offering more power and precision. They are versatile and can handle various pipe sizes and materials.

- CNC Pipe Bending Machines: Best for high-volume and complex bending tasks. These machines offer high precision, repeatability, and automation, making them ideal for large-scale production.

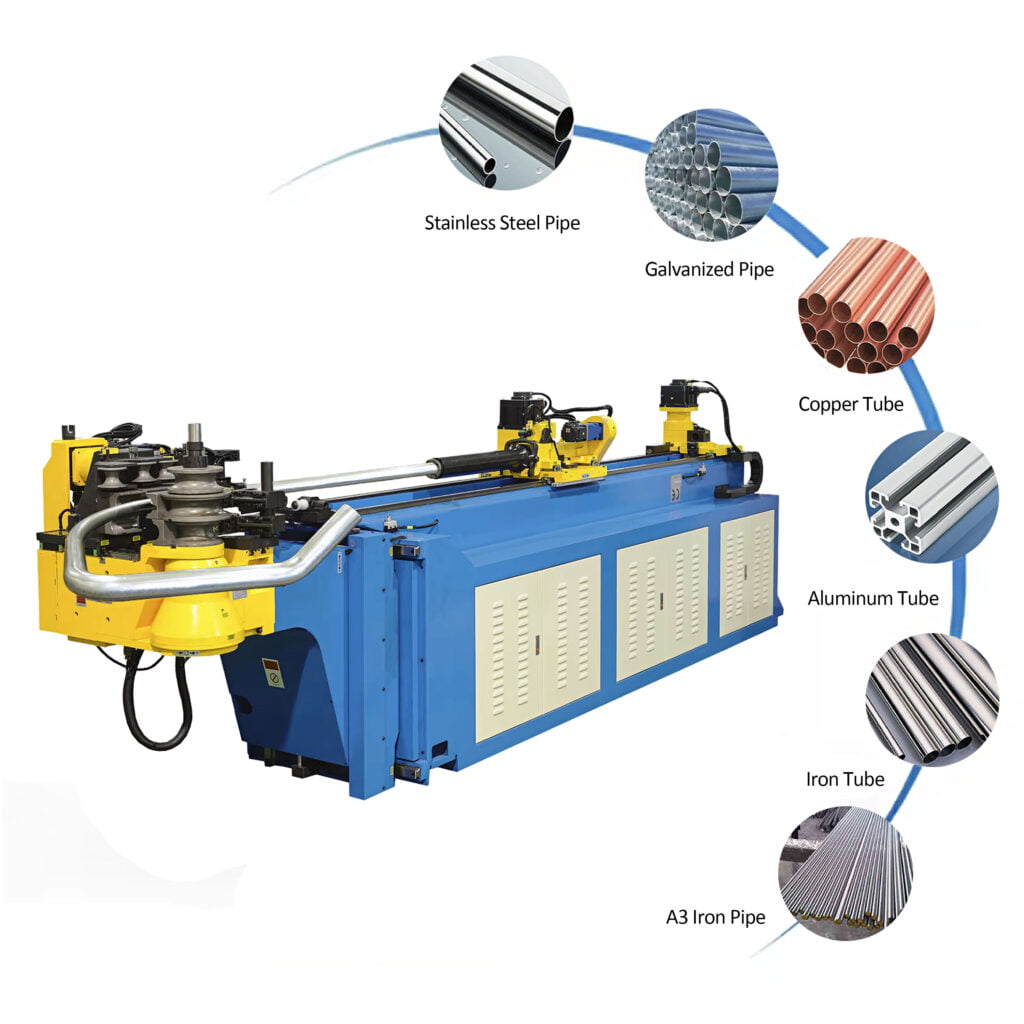

3. Material Compatibility

Ensure the machine you choose is compatible with the materials you will be using:

- Steel Pipes: Commonly used for wheelbarrow frames due to their strength and durability. The machine should be capable of handling steel without compromising on precision.

- Aluminum Pipes: Lighter but still durable, aluminum pipes require a machine that can bend without causing cracks or deformations.

- Other Materials: If you plan to use other materials, verify the machine’s compatibility and adjustability.

4. Technical Specifications

Evaluate the technical specifications of the machine to ensure it meets your needs:

- Bending Radius: The machine should offer a range of bending radii to accommodate different designs.

- Bending Angle: Check the maximum bending angle the machine can achieve.

- Pipe Diameter: Ensure the machine can handle the diameter of pipes you will be using.

- Speed and Efficiency: Consider the machine’s bending speed and overall efficiency to match your production timeline.

5. Ease of Use

The machine should be user-friendly and easy to operate:

- Control System: Look for intuitive control systems, especially for CNC machines, which often come with user-friendly interfaces and programming options.

- Setup and Adjustment: The machine should allow for easy setup and quick adjustments to minimize downtime.

6. Durability and Maintenance

Investing in a durable machine ensures long-term benefits:

- Build Quality: Choose machines made from high-quality materials that can withstand heavy use.

- Maintenance Requirements: Opt for machines that require minimal maintenance and come with clear instructions for upkeep.

- Spare Parts Availability: Ensure that spare parts are readily available to avoid long downtimes during repairs.

7. Safety Features

Safety is paramount in any manufacturing setting:

- Emergency Stop: The machine should have an easily accessible emergency stop button.

- Safety Guards: Ensure that the machine is equipped with safety guards to protect operators from moving parts.

- Operator Training: Confirm that training is provided for operators to handle the machine safely and effectively.

8. Cost and Budget

While quality is crucial, staying within budget is also important:

- Initial Investment: Compare prices and features to find a machine that offers the best value for your investment.

- Operating Costs: Consider the energy consumption and maintenance costs over the machine’s lifespan.

- Return on Investment: Evaluate the potential ROI based on the machine’s efficiency and the quality of output.

9. Supplier Reputation

Choose a reputable supplier to ensure quality and reliable support:

- Customer Reviews: Research customer reviews and testimonials to gauge the supplier’s reliability.

- After-Sales Support: Verify that the supplier offers comprehensive after-sales support, including training, maintenance, and technical assistance.

- Warranty: Ensure the machine comes with a warranty to protect your investment.

Related Articles

- Wheelbarrow Origins: Unveiling Production Details

- Semi-auto/Auto Pipe Bending Machine for Wheelbarrow Production

- How to Choose the Right Wheelbarrow Production Line

- How to Manufacture a Wheelbarrow: A Step-by-Step Guide by Jiuying

Choosing the right wheelbarrow pipe bending machine involves careful consideration of your production needs, machine types, material compatibility, technical specifications, ease of use, durability, safety features, cost, and supplier reputation. By evaluating these factors, you can select a machine that enhances your production efficiency and ensures high-quality output.

We hope this guide helps you in making an informed decision. For more information or assistance, feel free to contact us at Dalian Jiuying Heavy Machine Co., Ltd. We are dedicated to providing you with the best solutions for your manufacturing needs.

📞 Phone: +86-13394110095

📧 Email: liu@weldcnc.com

🌐 Website: https://www.toproductline.com/