In the demanding world of the oil and gas industry, the integrity and reliability of pipeline systems are paramount. Jiuying (JY) is proud to introduce our state-of-the-art JCO pipeline production line, meticulously designed to meet these stringent requirements. Our JCO pipelines are engineered to transport oil, natural gas, and other liquid or gaseous products, offering unmatched performance in terms of pressure resistance, temperature endurance, and corrosion resistance. This article delves into the production line’s workings, key features, and applications, illustrating why JY’s solutions are the industry’s preferred choice.

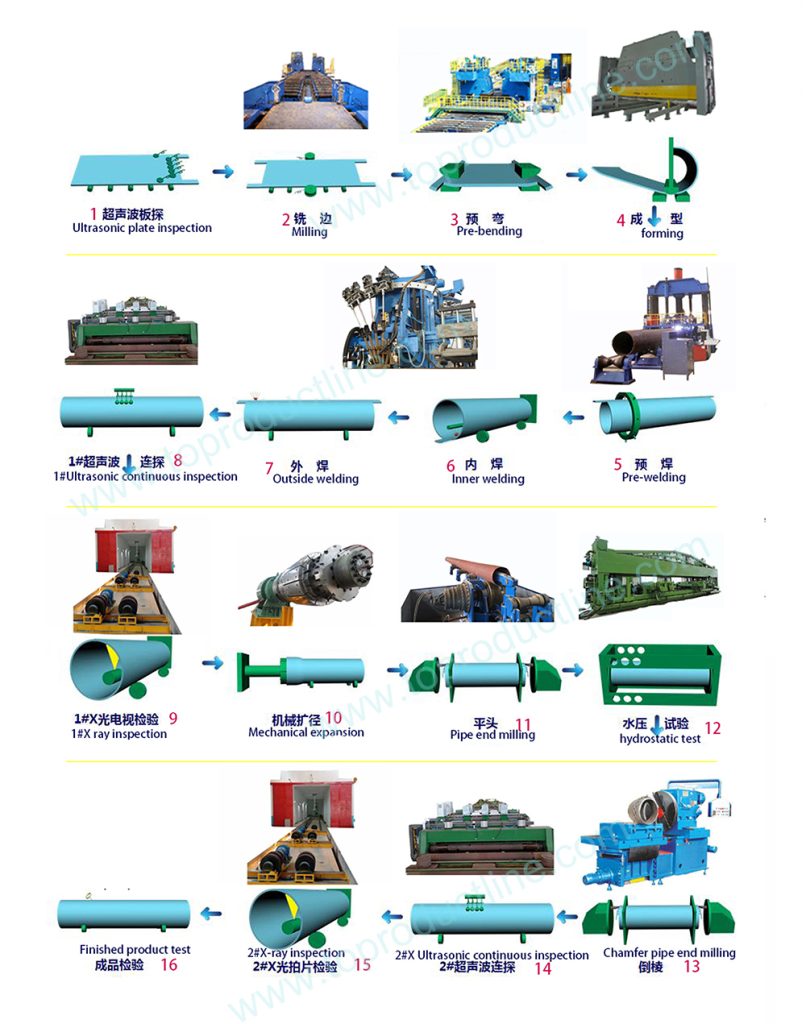

Production Line Process

Jiuying (JY) utilizes a meticulous and advanced production line process to manufacture high-quality JCO pipelines. Here’s an in-depth look at the steps involved:

1. Plate Preparation

High-quality steel plates are carefully selected and prepared for the production process. Each plate undergoes rigorous inspection to ensure it meets our stringent standards for strength, durability, and chemical composition.

2. JCO Forming

The steel plate is progressively formed into a pipe through the JCO process, which involves the following stages:

- J-Shape Forming: The steel plate is initially bent into a J-shape using specialized forming presses.

- C-Shape Forming: The plate is then further bent into a C-shape, ensuring gradual shaping and uniform thickness.

- O-Shape Forming: Finally, the plate is bent into an O-shape, completing the initial pipe formation. This incremental forming process ensures precise control over the pipe’s dimensions and enhances its structural integrity.

3. Welding

The formed pipe is welded using advanced automated welding techniques. This step is crucial for creating a strong and seamless joint that can withstand the high pressures and temperatures typical in oil and gas applications. Our welding systems ensure consistent, high-quality welds.

4. Heat Treatment

After welding, the pipes undergo heat treatment to relieve any residual stresses and improve their mechanical properties. This process enhances the pipe’s durability and performance, making it suitable for long-term operation in harsh environments.

5. Inspection and Testing

Each pipe is subjected to rigorous inspection and testing to ensure it meets all industry standards and specifications. This includes:

- Ultrasonic Testing: Detects any internal defects or inconsistencies within the pipe.

- Radiographic Inspection: Provides detailed images of the welds to ensure their quality.

- Hydrostatic Testing: Confirms the pipe’s ability to withstand high pressures by filling it with water and pressurizing it to a specified level.

6. Finishing and Coating

The pipes undergo finishing processes to ensure smooth surfaces and precise dimensions. They are also coated with protective materials to enhance corrosion resistance, ensuring long-term reliability and performance.

7. Final Quality Assurance

Before dispatch, each pipe undergoes a final quality assurance check to verify that it meets all required standards and specifications. This thorough inspection ensures that only the highest quality pipes are delivered to our customers.

If you want to know more detailed information, you can visit this website

Working Principle

The JCO pipeline production line operates on the principle of precise incremental forming and robust welding techniques. The process starts with a flat steel plate, which is incrementally bent into the J, C, and O shapes using a series of presses. This incremental forming process ensures uniform thickness and structural integrity throughout the pipe’s length. Once the pipe is formed, it is welded and heat-treated to ensure it can withstand the high pressures and temperatures typical in oil and gas applications. The final inspection phase ensures that only pipes meeting the highest standards are dispatched to our customers.

Product Features

JY’s JCO pipelines are renowned for their exceptional features:

- High Pressure and Temperature Resistance: Our pipelines are designed to operate under extreme conditions, maintaining structural integrity and performance.

- Excellent Corrosion Resistance: The materials and coatings used in our pipelines offer superior resistance to corrosion, ensuring longevity and reliability.

- Precision Manufacturing: The JCO process allows for precise control over dimensions, resulting in high-quality, uniform pipes.

- Robust Construction: Our pipes are built to withstand the mechanical stresses encountered during transportation and operation in harsh environments.

Application Scenarios

JY’s JCO pipelines are versatile and can be used in a variety of applications within the oil and gas industry:

- Onshore and Offshore Oil Transportation: Our pipelines are ideal for transporting crude oil from extraction sites to refineries.

- Natural Gas Distribution: Suitable for high-pressure natural gas transmission, ensuring safe and efficient delivery from production sites to end users.

- Chemical Processing Plants: Our pipelines are used to transport various chemical products, benefitting from their corrosion resistance and durability.

- Refineries and Petrochemical Facilities: These environments require pipelines that can withstand harsh chemicals and high temperatures, making JY’s JCO pipelines an excellent choice.

For more JCO pipeline applications, please visit this website

Why Invest in Building a JCO Pipe Production Line?

Investing in a JCO pipe production line offers numerous benefits, particularly for businesses in the oil and gas industry. Here’s a detailed look at why such an investment is worthwhile:

1. High Demand in the Oil and Gas Industry

The oil and gas industry relies heavily on robust and reliable pipeline systems for the transportation of oil, natural gas, and other liquid or gaseous products. With global energy demands continuing to rise, the need for high-quality pipelines is more critical than ever. Investing in a JCO pipe production line positions your business to meet this demand, ensuring a steady market for your products.

2. Superior Quality and Performance

JCO pipelines are known for their superior quality and performance characteristics:

- Pressure and Temperature Resistance: These pipelines are designed to withstand high pressures and extreme temperatures, making them ideal for harsh operational environments.

- Corrosion Resistance: JCO pipelines offer excellent resistance to corrosion, significantly extending their lifespan and reliability.

- Uniformity and Precision: The JCO forming process ensures that each pipe is uniform in thickness and dimension, enhancing its structural integrity.

3. Technological Advancement and Efficiency

A JCO pipe production line incorporates advanced manufacturing techniques that improve efficiency and reduce waste. The incremental forming process, coupled with automated welding and rigorous testing, ensures high productivity and consistent quality. This technological edge translates to lower operational costs and higher profitability over time.

4. Versatile Applications

JCO pipelines are versatile and can be used across various applications beyond the oil and gas industry, including:

- Chemical Processing Plants: For transporting various chemicals, benefiting from corrosion resistance and durability.

- Refineries and Petrochemical Facilities: Ideal for environments requiring pipes that can withstand harsh chemicals and high temperatures.

- Infrastructure Projects: Used in water supply systems and other critical infrastructure projects.

5. Long-Term Economic Benefits

Investing in a JCO pipe production line offers significant long-term economic benefits:

- Reduced Maintenance Costs: The high quality and durability of JCO pipelines mean lower maintenance and replacement costs.

- Extended Lifespan: The superior materials and construction techniques ensure a longer operational lifespan, providing a better return on investment.

- Market Competitiveness: Offering high-quality JCO pipelines enhances your market reputation and competitiveness, leading to increased business opportunities.

6. Strategic Industry Positioning

By investing in a JCO pipe production line, your business positions itself as a key player in the pipeline manufacturing sector. This strategic positioning can lead to partnerships with major oil and gas companies, government contracts, and other lucrative opportunities.

7. Environmental and Safety Standards Compliance

JCO pipelines are manufactured to meet stringent environmental and safety standards. Investing in this technology ensures compliance with global regulations, minimizing legal risks and promoting sustainable practices.

What do you need to consider when building a JCO pipe line?

Building a JCO pipe production line is a significant investment that requires careful planning and consideration. Here are the critical factors to keep in mind to ensure a successful setup and operation:

1. Market Demand Analysis

Before embarking on the construction of a JCO pipe production line, it’s essential to conduct a thorough market demand analysis:

- Industry Demand: Assess the current and projected demand for JCO pipelines in the oil and gas industry and other sectors such as chemical processing and infrastructure.

- Competitor Analysis: Analyze your competitors to understand their capabilities and market share.

- Customer Needs: Identify the specific needs of potential customers, including quality standards, pipeline dimensions, and delivery timelines.

2. Technological Requirements

A successful JCO pipe production line relies on advanced technology and machinery. Consider the following:

- Forming Machines: Invest in high-quality JCO forming presses that can handle various pipe diameters and thicknesses.

- Welding Equipment: In addition, use automated welding systems to ensure consistent, high-quality welds throughout the production process.

- Heat Treatment Facilities: Furthermore, make sure you have the necessary equipment for post-welding heat treatment, which enhances the mechanical properties of the pipes.

- Inspection and Testing Equipment: Finally, equip your facility with ultrasonic testing, radiographic inspection, and hydrostatic testing equipment to uphold rigorous quality assurance standards.

3. Raw Material Supply

The quality of your raw materials directly impacts the quality of your JCO pipelines. To ensure a reliable supply of high-quality steel plates, consider the following:

Supplier Selection: Begin by choosing reputable suppliers with a proven track record of delivering high-grade steel.

Material Specifications: Additionally, define clear specifications for the steel plates, including chemical composition, mechanical properties, and thickness, to meet your production standards.

4. Skilled Workforce

Operating a JCO pipe production line requires a skilled workforce:

- Training Programs: Begin by implementing comprehensive training programs for your staff to ensure proficiency in operating the machinery and adhering to safety protocols.

- Expert Technicians: Additionally, hire experienced technicians and engineers to oversee the production process and address any issues that may arise.

5. Quality Control

Quality control is paramount in pipeline production:

- Inspection Protocols: Establish rigorous inspection protocols at each stage of production, from raw material inspection to final product testing.

- Compliance Standards: Ensure your production process complies with industry standards and regulations, such as API (American Petroleum Institute) standards for pipelines.

6. Infrastructure and Space

Adequate infrastructure and space are essential for setting up a JCO pipe production line:

Facility Layout: Start by designing a facility layout that optimizes workflow and minimizes bottlenecks.

Storage Areas: Additionally, provide ample storage space for both raw materials and finished products.

Safety Measures: Furthermore, implement safety measures, such as proper ventilation, fire protection systems, and emergency response plans.

7. Environmental Considerations

Ensure your production line adheres to environmental regulations:

- Waste Management: Develop a waste management plan to handle scrap materials and other industrial waste.

- Emissions Control: Invest in emissions control systems to minimize the environmental impact of your production process.

- Sustainable Practices: Consider incorporating sustainable practices, such as recycling and energy-efficient machinery.

8. Financial Planning

Building a JCO pipe production line is a substantial financial investment:

- Budgeting: Create a detailed budget that includes machinery, raw materials, labor, and operational costs.

- Financing: Explore financing options, such as loans, grants, or investor funding, to support your project.

- Return on Investment: Conduct a financial analysis to estimate the return on investment and break-even point.

9. Supply Chain Management

Efficient supply chain management is crucial for uninterrupted production:

- Logistics: First, plan the logistics to ensure the timely delivery of raw materials and the efficient distribution of finished products.

- Inventory Management: Additionally, implement an inventory management system to track stock levels and avoid production delays.

10. Regulatory Compliance

Ensure compliance with all relevant regulations and standards:

- Permits and Licenses: Obtain the necessary permits and licenses to operate your production facility.

- Safety Regulations: Adhere to occupational health and safety regulations to protect your workforce.

- Industry Standards: Ensure your products meet industry standards, such as ISO certifications and API specifications.

Investing in a JCO pipe production line is a strategic decision with numerous benefits. It allows you to meet the high demand in the oil and gas industry while delivering superior quality products that ensure long-term economic gains. By leveraging advanced manufacturing techniques, you position your business as a market leader, securing a competitive edge and opening up new opportunities for growth and profitability.

For more information, you can view the following article

- Unlocking the Power of JCO Pipe Production Line for Factory Owners

- JCO/JCOE/LSAW pipe production line machines and equipments

- How to Mass Produce JCO Pipes: A Comprehensive Guide

Building a JCO pipe production line is a complex but rewarding endeavor that requires careful consideration of several key factors. These include market demand, technology, raw materials, workforce, quality control, infrastructure, environmental impact, financial planning, supply chain management, and regulatory compliance. By addressing these factors, you can establish a successful production line that meets the needs of the oil and gas industry and beyond.

Ready to Build? Contact JY Today!

For more guidance on setting up a JCO pipe production line, contact us. Our experts are here to assist you with every step of the process.

Why Choose Jiuying (JY) for Your JCO Pipe Production Line?

When it comes to investing in a JCO pipe production line, choosing the right supplier is crucial for ensuring quality, reliability, and long-term success. Here are compelling reasons why Jiuying (JY) is the best choice for your JCO pipe production line needs:

1. Expertise and Experience

With extensive experience in manufacturing and supplying high-quality production lines for the oil and gas industry, Jiuying (JY) brings unparalleled expertise to the table. Our deep understanding of the industry’s unique demands, coupled with our technical proficiency, enables us to deliver state-of-the-art solutions that consistently exceed customer expectations.

2. Cutting-Edge Technology

t JY, we leverage the latest technological advancements in our production lines. Specifically, our JCO pipe production lines incorporate cutting-edge forming, welding, and heat treatment technologies. As a result, this approach ensures that your pipes are manufactured to the highest standards of precision and durability.

3. Superior Quality Assurance

At JY, we prioritize quality in every aspect of our operations. To achieve this, our production lines are equipped with robust quality control systems, such as ultrasonic testing, radiographic inspection, and hydrostatic testing. Consequently, these rigorous measures ensure that each pipe undergoes thorough scrutiny and meets stringent industry standards. Moreover, our unwavering commitment to quality assurance guarantees that our customers receive products of exceptional quality and reliability.

4. Customization and Flexibility

At JY, we recognize that each customer has unique requirements. Therefore, we offer highly customizable production lines that are tailored to meet your specific needs. Whether you require specific pipe dimensions, particular material grades, or specific production capacities, we can design and construct a production line that aligns perfectly with your precise specifications.

5. Comprehensive Support and Service

Choosing JY means more than just buying a production line; it means partnering with a team dedicated to your success. We offer:

- Installation and Commissioning: Our experts will guide you through the installation and commissioning process of your production line, ensuring seamless operation from the outset.

- Training Programs: We offer extensive training programs to equip your personnel with the skills needed to operate and maintain the equipment effectively.

- Technical Support: Our dedicated technical support team is available around the clock to address any queries or issues promptly, thereby minimizing downtime and maximizing productivity.

- Maintenance Services: We provide regular maintenance services to keep your production line running smoothly and efficiently, enhancing both longevity and reliability.

By choosing JY, you gain access to not only cutting-edge technology and customized solutions but also comprehensive support throughout the lifecycle of your production line.

6. Proven Track Record

JY has a proven track record of delivering high-quality production lines to satisfied customers worldwide. Our commitment to excellence and customer satisfaction has earned us a strong reputation in the industry.

7. Competitive Pricing

In addition to our stellar track record, we offer competitive pricing that does not compromise on quality. Leveraging efficient manufacturing processes and economies of scale, we ensure our production lines provide exceptional value for your investment.

8. Strong Global Presence

Furthermore, JY maintains a robust global presence, positioning us ideally to cater to customers across the globe. Our extensive network enables timely delivery, localized support, and a deep understanding of regional market dynamics and needs.

9. Environmental and Safety Compliance

At JY, we prioritize environmental sustainability and safety. Our production lines are meticulously crafted to lessen environmental impact and conform rigorously to all applicable safety regulations. Moreover, we are devoted to assisting you in achieving your environmental and safety goals.

Choosing Jiuying (JY) for your JCO pipe production line means partnering with a trusted leader in the industry. By leveraging our expertise, advanced technology, and unwavering commitment to quality, we ensure you receive comprehensive support. Thus, we become the ideal choice for fulfilling your production needs.

Ready to Invest? Contact JY Today!

For more information on our JCO pipe production lines and how they can benefit your business, contact us. Our team of experts is ready to assist you with all your inquiries and help you make an informed decision.