Welcome to Dalian Jiuying Heavy Machinery Equipment Co., Ltd.!

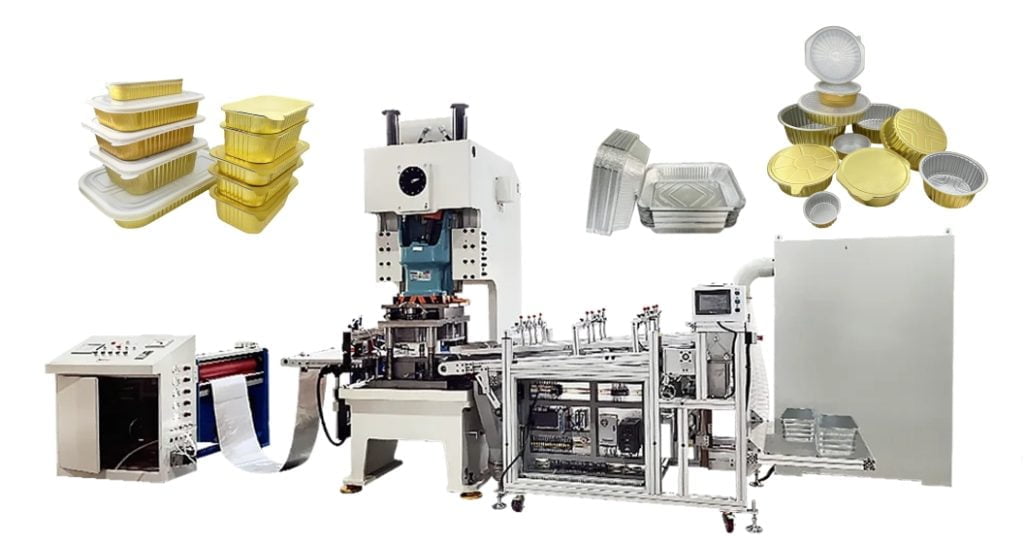

Aluminum foil food container production line

Learn more about our products and services

About us

Jiuying product line

Jiuying Machinery Equipment Co., Ltd. is a professional enterprise specializing in the research, development, production, and sales of aluminum foil lunch box production lines. Headquartered in China, the company has a passionate and innovative team dedicated to providing high-quality products and services to global customers. Guided by the core values of quality, innovation, service, and responsibility, we continuously pursue technological innovation to ensure the improvement of product quality and service standards. Through strict quality management and a comprehensive pre-sales, in-sales, and after-sales service system, Jiuying Machinery Equipment Co., Ltd. works collaboratively with customers to create a better future.

At Jiuying, as we strive for the material and spiritual well-being of all, we elevate our service with love and integrity, aiming to equip China and equip the world.

OUR CEO

Main machines of the production line

Our production lines revolutionize aluminum foil food container manufacturing with seamless automation, precision engineering, and superior quality control.

Auto feeder machine

Punching press

Auto box packed

Auto waster recycling

Aluminum foil food container manufacturing Process

The humble aluminum foil food container is a staple in the food industry, offering convenience and practicality. Have you ever wondered how these containers are made? In this article, we’ll walk you through the essential machines in the aluminum foil food box production line, from the initial stages to the final packaging.

Auto feeder

The production process begins with the auto feeder. This machine efficiently feeds the aluminum foil material into the next stages of production, ensuring a continuous workflow.

Auto feeder of aluminum Foil food Box/container Production Line Basic configuration:

◆Research control drive ◆Mitsubishi series PLC ◆Shenzhen Samkoon seven-inch touch color screen ◆Japan Izumi relay ◆Excellent switching power supply ◆Domestic high-quality servo motor

Auto feeder of aluminum Foil food Box/container Production Line Performance description:

◆The material rack and the feeding head are designed separately, and the feeding head is installed on the punching machine, which is convenient for feeding adjustment.

◆The frame adopts an integral all-steel structure, superimposed modules, and high feeding accuracy.

◆Zero-tension free tracking feeding is adopted, and the left-right centering adjustment is convenient and quick.

◆The unwinding tension adopts imported magnetic powder brake, which is suitable for long-term uninterrupted work.

◆The feeding machine is convenient and simple to unwind; the feeding is simple; the double stick is easy to refuel, and the oil tank capacity is super large.

Punching Machine

The auto stamping punching press machine is the heart of the production line. It takes the aluminum foil and shapes it into the desired container form, creating the structure for packaging food. Precision and consistency are crucial, and this machine delivers both.

- Role: Creates water holes and 1/8 round corners.

- Functionality Overview: The Punching Machine employs a mechanical or hydraulic system to punch required holes and shapes into the metal sheet. This includes the precise creation of water holes and small round corners (1/8), essential for the functionality and aesthetics of the sink. The ability to execute these tasks with high precision is vital for ensuring consistent quality.

Auto Box Packing Machine

Once the aluminum foil has been expertly transformed into food containers, the auto box packing machine takes over. It efficiently packs these containers, making them ready for storage and distribution. This step ensures that the containers remain in perfect condition until they reach the end-users.

Auto Box Packed Machine for Aluminum Foil Food Container Production Line

Our machine offers several advantages over others in the market:

1. Enhanced Stability: Specifically designed for thin raw materials, our machine ensures stable operation even with thin materials, guaranteeing consistent and reliable production.

2. Convenient Material Position Adjustment: Our machine facilitates easy adjustment of material positions, minimizing material waste caused by position deviations during adjustments.

3. Easy Auto Stacker Adjustment: The Auto Stacker adjustment feature is user-friendly and ensures seamless automatic operation, enhancing overall efficiency.

4. Intelligent Programming: With intelligent programming capabilities, our machine can store over a hundred mold specifications, allowing for versatile production options.

5. High-Speed and Steady Design: Engineered for high-speed operation and trouble-free performance, our machine ensures continuous and efficient production.

Specifications:

– Conveyor Belt Width: 600mm

– Receiving Belt Height: 920 +/- 25mm (customizable)

– Maximum Lunch Box Size: 500*300mm (1 channel), 300*250mm (5 channels)

– Maximum Stacking Height: 420mm (depending on lunch box size)

– Air Consumption (1 Channel): 0.2m3/min

– Machine Power: 4KW

Upgrade your production line with our advanced Auto Box Packed Machine, delivering superior performance and efficiency.

Auto Waste Recycling Equipment

Sustainability is a growing concern in today’s world. The auto waste recycling equipment is an essential component of the production line. It collects any waste or excess materials and processes them for recycling. This eco-friendly approach reduces waste and contributes to a more sustainable production process.

Auto Waste Recycling Equipment for Aluminum Foil Food Container Production Line

The Auto Waste Recycling Equipment for Aluminum Foil Food Container Production Line is essential for efficient recycling of aluminum foil scraps, streamlining production, transportation, and recycling processes. It includes:

Fully Automatic Hydraulic Packing and Briquetting Machine: Effectively compacts aluminum foil scraps into briquettes for easy handling and recycling.

Waste Suction Fan System: Facilitates the collection of waste materials from production lines, ensuring a clean and efficient working environment.

Waste Material Exhaust Ducts: Channels waste materials away from production areas, maintaining cleanliness and safety.

This recycling equipment system is designed to cater to the needs of up to 3 production lines, with the flexibility to accommodate additional lines by simply adding the waste suction fan system.

As an integral component of the Aluminum Foil Food Container Production Line, this product plays a crucial role in waste management and resource optimization. For more information on our Aluminum Foil Food Container Production Line machines and equipment, please click to view details or contact us directly.

Best automatic aluminum foil container production line:

Automatic equipment feeding, automatic stamping, automatic box packing, and automatic waste absorption and pressing into blocks.

Smooth and efficient automated production, one person can complete equipment operation and finished product packaging, and the automatic line runs at a stable speed of 40-50 times/min

The degree of intelligence is high, the automatic shutdown of the detection of the discharge failure and the automatic shutdown of the failure of the collection box can ensure the safe operation of the equipment and reduce human interference.

24-hour continuous work

The service life of the mold exceeds 10 million times

Application scenarios

Aluminum foil lunch box can produce lunch box style case show

If you want to know more about Aluminum foil food container production line manufacturing issues, please contact us directly

Why us

The optimal choice for the purchase of this line

Jiuying has been deeply involved in the machinery industry and has achieved good cooperative relations with many factories. It has strong resource integration capabilities and can customize different production lines according to your production needs.

- Understand global market trends

- Many choices of machines

- High level of product customization

- Better cost control

Multilingual communication

Foreign trade firms excel in multilingual communication, ensuring smooth interactions with global clients.

Support Always

Comprehensive, round-the-clock customer support.

Quality First

Strict quality control for unparalleled product excellence.

Tailored Solutions

Custom-fit production lines to meet unique demands.

professional service

Our team

Mainly serving the English market

Email:belinda@weldcnc.com

Whatsapp/wechat: +86 15542318526

Mainly serving the Spanish-speaking market

Email: liu@weldcnc.com

Whatsapp/Wechat:+8613394110095

Mainly serving the Russian-speaking market

Email:kelly@weldcnc.com

Whatsapp/wechat: +86-138 4288 2706

Brand Certification

Our Certification

shearing machine bending machine rolling machine

bending machine

Combined punching and shearing machine

hydraulic press

ORDER NOW

Order Steps

Consultation and Quotation

Determine order details

Production and Delivery

Installation and Support

If you have any questions, please contact us at any time,

Wechat/whatsapp: 0086-13394110095 Email: liu@weldcnc.com

customer reviews

Hear from our clients

“Our productivity has soared since we implemented this aluminum foil lunch box production line. It’s efficient, and the end products are top-notch. We’re very pleased with our purchase.”

“The aluminum foil lunch box production line has significantly boosted our production capacity. The efficiency and minimal waste make it a cost-effective solution. Highly recommended!”

“This production line is incredibly efficient and easy to operate. We’ve seen a noticeable improvement in our output and product quality. It’s been a fantastic addition to our manufacturing process.”

Blog & News

Reads Our Latest Blogs

How Much Does It Cost to Invest in an Aluminum Foil Container Factory?

Opening an aluminum foil container factory involves several investments in materials, equipment, and infrastructure. This article will discuss the working

Understanding the Aluminum Foil Lunch Box Production Line essential knowledge

Aluminum foil lunch boxes are popular for their convenience and eco-friendliness, driving demand for efficient production lines. This guide covers

Auto Feeder For Aluminum Foil Food Box/Container Production Line

The auto feeder is a critical component in the aluminum foil food box/container production line. It enhances efficiency and precision in the manufacturing process.

FAQ

The main components typically include the feeding system, punching and forming unit, trimming section, and the stacking and packing unit. Each part works together to transform raw aluminum foil into finished lunch boxes.

The production capacity varies depending on the specific model and configuration of the production line. Generally, it can produce thousands of lunch boxes per hour. For precise numbers, please refer to the specifications of the specific model you are interested in.

Power requirements vary based on the size and type of the production line. Typically, a standard line requires a 380V/50Hz power supply. Detailed power specifications can be found in the product manual.

The space required depends on the model and configuration of the production line. On average, you will need a workshop area of approximately 100 to 200 square meters to accommodate the equipment and ensure smooth operation.

Regular maintenance is crucial for optimal performance. It is recommended to conduct daily inspections, weekly cleaning, and monthly comprehensive checks. Detailed maintenance guidelines are provided in the user manual.

Yes, we offer comprehensive training for your staff to ensure they are proficient in operating and maintaining the production line. Training can be conducted on-site or remotely, depending on your preference.

We provide 24/7 technical support to address any issues that may arise. Our support includes remote assistance, on-site service, and access to a dedicated customer service hotline.

Yes, we maintain a stock of commonly required spare parts to ensure minimal downtime in case of a breakdown. Spare parts can be ordered directly from us and are shipped promptly.

The production line comes with a one-year warranty that covers manufacturing defects and parts replacement. Extended warranty options are also available upon request.

Yes, we offer customization options to meet specific production requirements. Customizations can include adjustments to production capacity, mold designs, and additional features to enhance functionality.