H-beam profile production line

🔧 User-Friendly Operation

📞 24/7 Support

🚀 Efficient Production

💎 Quality Assurance

State-of-the-Art Technology

Utilizes the latest machinery and technology for precise and efficient H-beam production.

Customization and Flexibility

Tailored solutions to meet your specific project requirements and production needs.

Proven Expertise

Years of industry experience and a strong track record in H-beam manufacturing

ABOUT US

Jiuying product line

At Jiuying, we are at the forefront of the machinery manufacturing industry, specializing in the development and production of advanced H-Beam production lines. Our mission is to deliver efficient, reliable, and innovative production solutions tailored to meet the specific needs of our clients.

H-beam profile production line

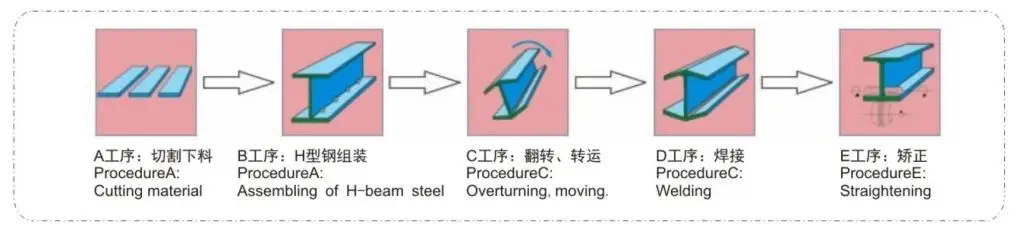

Step 1: Cutting

Flame & Plasma Cutting Machine

- Role: This machine is used to cut steel plates into the required sizes and shapes for H-beam production. It provides precise and efficient cutting, ensuring the foundational components are accurately prepared.

Step 2: Assembling

H-Beam Profile Assembling Machine

- Role: This machine assembles the cut steel plates into H-beam profiles. It ensures accurate alignment and positioning, which is critical for the subsequent welding process.

Step 3: Welding

Gantry Type Welding Machine

- Role: This machine performs the welding of the assembled H-beam profiles. It ensures strong and consistent welds, forming the core structure of the H-beam.

Step 4: Straightening

Straightening Machine

- Role: This machine corrects any deformations that occur during the welding process. It ensures the H-beams are perfectly straight, meeting the required specifications and standards.

Step 5: Surface Treatment

Shot Blasting Machine

- Role: This machine cleans the surface of the H-beams by removing rust, scale, and other impurities. It prepares the surface for painting, ensuring better adhesion and finish.

Step 6: Painting

Spray Painting Machine

- Role: This machine applies a uniform coat of paint to the H-beams, providing corrosion resistance and enhancing their appearance. It ensures a high-quality finish that meets industry standards.

Role:

The Flame & Plasma Cutting Machine is the first step in the production process, responsible for cutting steel plates into the required dimensions for H-beam production. This machine uses high-temperature flames and plasma to achieve precise and clean cuts.

- Precision Cutting: Ensures the steel plates are cut to exact specifications, reducing waste and improving material efficiency.

- Versatility: Can cut various thicknesses and types of steel plates, making it suitable for diverse production needs.

- Efficiency: Provides rapid cutting speeds, increasing overall production throughput.

Role:

The H-Beam Profile Assembling Machine is used to assemble the cut steel plates into H-beam profiles. This machine ensures accurate alignment and positioning of the flanges and web before welding.

- Accurate Assembly: Aligns and positions the steel plates precisely, ensuring the correct geometry of the H-beam.

- Ease of Operation: Automated features facilitate easy and quick assembly, reducing manual labor and error.

- Consistency: Ensures uniformity in the assembly process, which is critical for subsequent welding quality.

Role:

The Gantry Type Welding Machine performs the welding of the assembled H-beam profiles. This machine ensures that the welds are strong, consistent, and meet quality standards.

- Strong Welds: Provides deep and strong weld penetration, ensuring the structural integrity of the H-beams.

- Automation: Automated welding processes enhance precision and reduce manual intervention.

- Consistency: Ensures uniform weld quality across all H-beams, meeting industry standards.

Role:

The Straightening Machine corrects any deformations that occur during the welding process. It ensures the H-beams are perfectly straight, meeting the required specifications and tolerances.

- Precision Straightening: Corrects distortions caused by welding, ensuring the beams are straight and true.

- Quality Control: Enhances the structural integrity and aesthetic quality of the H-beams.

- Efficiency: Rapid straightening processes increase production efficiency.

Role:

The Shot Blasting Machine cleans the surface of the H-beams by removing rust, scale, and other impurities. This process prepares the surface for painting, ensuring better adhesion and finish.

- Surface Cleaning: Removes surface contaminants, providing a clean and smooth finish.

- Preparation for Coating: Enhances paint adhesion, improving the durability and appearance of the H-beams.

- Environmental Compliance: Ensures the surface treatment process meets environmental standards.

Role:

The Spray Painting Machine applies a uniform coat of paint to the H-beams, providing corrosion resistance and enhancing their appearance. This machine ensures a high-quality finish that meets industry standards.

- Uniform Coating: Ensures even and consistent paint application, enhancing corrosion protection.

- High-Quality Finish: Provides a professional finish, improving the aesthetic appeal of the H-beams.

- Efficiency: Automated spraying reduces paint waste and increases production speed.

At Jiuying, as we strive for the material and spiritual well-being of all, we elevate our service with love and integrity, aiming to equip China and equip the world.

OUR CEO

Application scenarios

H-beam profile production line Application Areas

Construction and Infrastructure

Transportation

H-beams are crucial in the manufacturing of transportation infrastructure and vehicles, ensuring safety and performance.

Industrial Machinery

H-beams support various industrial machines and equipment, ensuring stability and operational efficiency.

Energy Sector

H-beams play a significant role in constructing energy infrastructure, including power plants and renewable energy projects.

Manufacturing

H-beams are vital in the manufacturing industry, providing support for production lines and factory structures.

Residential Construction

H-beams are used in residential construction, providing structural support for homes and residential buildings.

If you want to know more about Light pole production line manufacturing issues, please contact us directly

ORDER NOW

Order steps

Consultation and Quotation

Determine order details

Production and Delivery

Installation and Support

If you have any questions, please contact us at any time,

Wechat/whatsapp: 0086-13394110095 Email: liu@weldcnc.com

Contact Us

Tel:+86-13394110095

Fax:+86-411-39015062

Wechat/Whatsapp:+86-13394110095

Email:liu@weldcnc.com

Add:20# Ganwan Street, Zhongshan District, Dalian City, China

professional service

Our team

Mainly serving the English market

Email:belinda@weldcnc.com

Whatsapp/wechat: +86 15542318526

Mainly serving the Spanish-speaking market

Email: liu@weldcnc.com

Whatsapp/Wechat:+8613394110095

Mainly serving the Russian-speaking market

Email:kelly@weldcnc.com

Whatsapp/wechat: +86-138 4288 2706

Brand Certification

Our Certification

shearing machine bending machine rolling machine

bending machine

Combined punching and shearing machine

hydraulic press

customer reviews

Hear from our clients

“Jiuying’s H-beam profile equipment has significantly boosted our production efficiency. The precision and durability of the machinery are outstanding.”

“We upgraded our production line with Jiuying’s equipment, and the results have been impressive. The automation features have reduced errors and sped up our processes.”

“Since implementing Jiuying’s H-beam profile equipment, our product quality has improved, and operating costs have decreased. Highly recommend their solutions.”

Why choose our production line

The optimal choice for the purchase of this line

Choosing Jiuying’s H-Beam production line means investing in a solution that combines cutting-edge technology, customization, proven expertise, comprehensive support, quality assurance, cost-efficiency, and a customer-centric approach. Our commitment to excellence ensures that you receive not just a product, but a partnership dedicated to your success.

✨ State-of-the-Art Technology

Our production line integrates cutting-edge machinery to ensure precise and efficient H-beam manufacturing.

🔧 Customization and Flexibility

We offer tailored solutions to meet your specific project requirements and production needs.

🏆 Proven Expertise

With years of industry experience, we have a strong track record in H-beam manufacturing.

💰 Cost-Effective Solutions

Our optimized processes reduce costs and enhance your return on investment.

🔍 Quality Assurance

We adhere to stringent quality standards, ensuring reliable and durable H-beams.

Blog & News

Reads Our Latest Blogs

Water Heater Inner Tanks Process-Jiuying Tank Production Line

The inner tank is a crucial component of water heaters, responsible for storing and heating water efficiently. The production of

Straightening Machine for H-Beam Profile Production Line: A Comprehensive Guide

In the fast-paced and ever-evolving industrial landscape, efficiency and precision are paramount. As industries like automotive

Exploring the Versatile Applications of H-Beam Production Lines

In industries ranging from household utilities to industrial applications, Liquefied Petroleum Gas (LPG) cylinders play a crucial role.

FAQ

General Information

The production capacity varies depending on the specific configuration and machinery used. Please contact us for detailed information based on your requirements.

Yes, we offer tailored solutions to meet your specific project requirements and production needs.

Our production line is designed to process various steel types, including carbon steel, stainless steel, and alloy steel.

Technical Specifications

The dimensions of the H-beams can be customized based on your specifications. Standard sizes range from small beams to large structural components.

The power requirement varies depending on the specific machinery and production line configuration. Please contact us for detailed information.

The Flame & Plasma Cutting Machine ensures high precision with minimal material waste, achieving cuts accurate to industry standards.

Installation and Operation

Installation time varies based on the complexity and size of the production line. Generally, it takes several weeks to a few months, including setup and testing.

Yes, we offer comprehensive training for your staff to ensure smooth and efficient operation of the production line.

Yes, we provide ongoing technical support and maintenance services to ensure your production line operates efficiently.

Maintenance and Service

Regular maintenance is essential for optimal performance. We provide a detailed maintenance schedule and support to help you keep the machinery in top condition.

Yes, we supply spare parts and components for all our machinery to ensure minimal downtime and continuous operation.

Contact our technical support team immediately. We offer remote assistance and on-site service to resolve any issues quickly.

Purchasing and Orders

You can contact us directly through our website, email, or phone. Our sales team will assist you with the ordering process.

Lead times vary based on the complexity and size of the production line. Typically, it ranges from a few weeks to several months.

Yes, we offer flexible financing options to help you manage the investment in your production line. Please contact us for more details.

Quality and Compliance

Yes, our products meet industry standards and are certified for quality and safety.

We implement stringent quality control measures at every stage of production, from raw material sourcing to final assembly and testing.

Yes, we provide all necessary documentation and certifications, including user manuals, maintenance guides, and compliance certificates.

Customization and Upgrades

Yes, our production lines are designed with scalability in mind, allowing for future upgrades and expansions.

We offer a range of customization options, including machinery specifications, production capacities, and additional features to meet your unique needs.

Environmental and Safety

Our production lines are designed to minimize waste and energy consumption, adhering to environmental regulations and promoting sustainable practices.

Yes, our machinery includes advanced safety features to protect operators and ensure a safe working environment.

We provide waste management solutions and guidelines to help you handle and dispose of by-products responsibly.

Delivery and Logistics

Yes, we provide international shipping and logistics services to deliver our production lines worldwide.

Shipping and handling charges vary based on the destination and size of the production line. Please contact us for a detailed quote.

We use specialized packaging and logistics partners to ensure the safe and secure transportation of our machinery.

After-Sales Service

We offer a range of after-sales services, including technical support, maintenance, spare parts supply, and training.

Yes, our team provides on-site installation and commissioning services to ensure your production line is set up correctly.

Yes, we provide remote support through phone, email, and online platforms to assist with any troubleshooting needs.

You can reach our customer support team through our website, email, or phone. We are always ready to assist you with any questions or concerns.