Top-Quality Sieve Production Line

Reliable and Cost-Effective Solutions

Our sieve production line delivers consistent, high-quality results for all your sieving needs.

High Efficiency

Our equipment employs the latest technology to ensure fast and efficient production, thereby boosting overall productivity.

Customer Support

We provide comprehensive pre-sales and after-sales services to ensure clients receive full support during equipment selection, installation, commissioning, and maintenance.

Cost Savings

By optimizing production processes and improving efficiency, our equipment helps clients significantly reduce manufacturing costs.

ABOUT US

Jiuying product line

Our company specializes in providing efficient and precise industrial equipment, including sieve production lines and metal rod straightening machines. With cutting-edge technology and superior product quality, we are dedicated to helping our clients optimize their production processes, enhance product quality, and reduce manufacturing costs.

At Jiuying, as we strive for the material and spiritual well-being of all, we elevate our service with love and integrity, aiming to equip China and equip the world.

OUR CEO

Sieve Production Line Production Process

Step 1: Material Preparation

- Hydraulic Plate Shears Machine

- Role: This machine cuts metal plates to the required dimensions. It ensures precise and clean cuts, which is essential for preparing the raw materials for further processing.

Step 2: Bending and Shaping

Hydraulic Plate Bending Machine

- Role: The cut metal plates are then bent into the desired angles and shapes. This machine is crucial for forming the structural components of the sieves with consistent and accurate bends.

Rolling Machine

- Role: This machine rolls the metal plates into cylindrical or other required forms. It provides the necessary shapes for different types of sieves, enabling diverse applications.

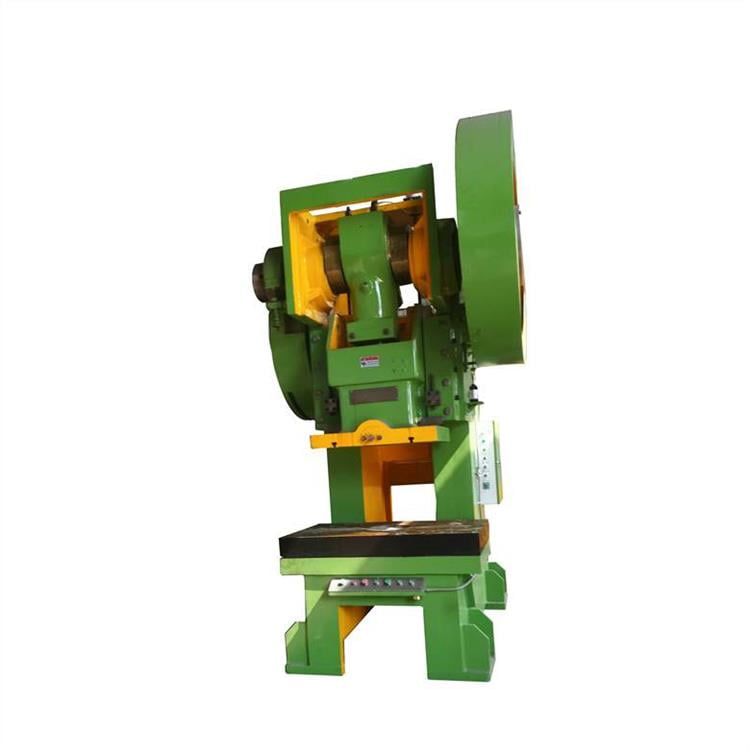

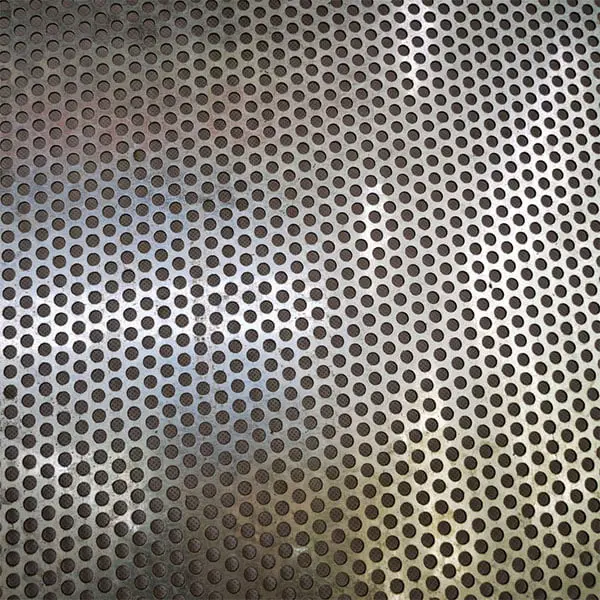

Step 3: Punching and Perforation

Punching Press Machine

- Role: The next step involves creating holes and perforations in the metal plates. This machine is fundamental for the sieve’s functionality, allowing for the proper filtration and separation of materials.

CNC Turret Punching Machine

- Role: This automated machine enhances the punching process by providing precise and efficient perforation. It enables the production of complex patterns and multiple holes on the sieve plates with high accuracy.

Step 4: Marking and Finishing

- Desktop Laser Marking Machine

- Role: Finally, this machine provides precise and permanent marking on the sieves, such as branding, model numbers, or specifications. This step ensures traceability and quality assurance.

Application scenarios

Rice sieve production line

Food Processing Industry

- Used for sieving and filtering food products such as flour, sugar, grains, and spices to ensure purity and quality.

Pharmaceutical Industry

- Essential for pharmaceutical manufacturing processes, including the separation and classification of pharmaceutical ingredients.

Chemical Industry

- Utilized in chemical processing to separate and classify different chemical compounds and materials.

Mining and Aggregate

- Plays a crucial role in the mining and aggregate industries for separating minerals, ores, and aggregates of varying sizes.

Water Treatment

- Used in water treatment facilities for filtration processes to remove impurities and ensure water quality.

Construction

- Applied in the construction industry for grading and separating construction materials like sand, gravel, and aggregates.

Environmental Protection

- Essential in environmental applications for soil testing and remediation, ensuring environmental safety and compliance.

Recycling

- Used in recycling plants for sorting and separating recyclable materials such as plastics, metals, and paper.

If you want to know more about rice sieve production line manufacturing issues, please contact us directly

professional service

Our team

Mainly serving the English market

Email:belinda@weldcnc.com

Whatsapp/wechat: +86 15542318526

Mainly serving the Spanish-speaking market

Email: liu@weldcnc.com

Whatsapp/Wechat:+8613394110095

Mainly serving the Russian-speaking market

Email:kelly@weldcnc.com

Whatsapp/wechat: +86-138 4288 2706

Brand Certification

Our Certification

shearing machine bending machine rolling machine

bending machine

Combined punching and shearing machine

hydraulic press

ORDER NOW

Order Steps

Consultation and Quotation

Determine order details

Production and Delivery

Installation and Support

If you have any questions, please contact us at any time,

Wechat/whatsapp: 0086-13394110095 Email: liu@weldcnc.com

customer reviews

Hear from our clients

“Our productivity has soared since we implemented this aluminum foil lunch box production line. It’s efficient, and the end products are top-notch. We’re very pleased with our purchase.”

“The aluminum foil lunch box production line has significantly boosted our production capacity. The efficiency and minimal waste make it a cost-effective solution. Highly recommended!”

“This production line is incredibly efficient and easy to operate. We’ve seen a noticeable improvement in our output and product quality. It’s been a fantastic addition to our manufacturing process.”

Why us

Why Choose Our Sieve Production Line?

At Jiuying, we take pride in offering a superior Sieve production line equipped with advanced technology and tailored solutions to meet your industry's specific needs.

✨Advanced Technology

Incorporates cutting-edge machinery for precise manufacturing of sieves.

🌐 Industry Expertise and Reliability

Trusted by sectors like food processing, pharmaceuticals, and mining.

🔧 Customization and Flexibility

Tailored solutions to meet specific industry requirements.

👨🔧 Comprehensive Support

From consultation to installation, ensuring seamless operation.

💲 Cost Efficiency

Optimizes processes for economic benefits and ROI.

Blog & News

Reads Our Latest Blogs

A Guide to the Perforated Sheet Production Line

Perforated metal sheets are essential in various industries, from architecture to automotive manufacturing. But how are these intricate sheets produced?

Introduction to Our Perforated Sheet Product Line

Our perforated sheet product line is designed to meet a wide range of industrial needs, offering precision and efficiency for various applications. Whether you need

Enhancing Efficiency with Jiuying’s Sieve Production Line

Discover how Jiuying’s advanced Sieve production line optimizes industrial processes across diverse sectors. From precise cutting and shaping with hydraulic

FAQ - Sieve Production Line

You can easily place an order by contacting our sales team directly via email or phone. Visit our website for more information on contacting us.

We provide comprehensive after-sales support, including installation, training, and ongoing technical assistance to ensure smooth operation and maintenance of your equipment.

Our products are typically packaged in sturdy wooden crates or iron crates to ensure safe transportation and delivery.

Yes, we specialize in customizing production lines to meet specific requirements, including design, size, and functionality. Contact us to discuss your customization needs.

We offer a warranty on our products. Specific terms and conditions may vary; please inquire for detailed warranty information.

Yes, our team provides installation services and technical support to ensure proper setup and functionality of your production line equipment.

Technical support is available through our dedicated support team via phone, email, or on-site visits as needed. We are committed to resolving any technical issues promptly.

Yes, we offer training programs to educate your team on the operation, maintenance, and safety procedures of our production line equipment.

Lead times vary based on product specifications and current production schedules. Contact our sales team for estimated delivery times upon placing your order.

For pricing inquiries and quotes, please contact our sales team directly. We will provide detailed pricing information based on your specific requirements.