In modern manufacturing industry, trolley As an important transportation tool, it is widely used in construction, agriculture, horticulture and other fields. Nine Win offers a wheelbarrow production line to bring customers an efficient and reliable production solution. This article will detail the components of a unicycle, the machines needed for the production process of a wheelbarrow production line, the application scenarios and the higher level of electric wheelbarrow production line production methods.

To understand the production process of a wheelbarrow, you first need to understand its components

What are the components of a wheelbarrow?

Individual modules of the wheelbarrow production line

Tray/Bucket:

- Material: Typically made from metal (such as steel or aluminum) or heavy-duty plastic.

- Function: Used for holding and transporting materials such as soil, sand, gravel, or construction materials.

- Features: Designed with high sides to prevent materials from spilling during transport.

Frame:

- Material: Usually constructed from metal for strength and durability.

- Function: Provides structural support for the tray and connects to other components like the handles and wheel.

- Features: Must be sturdy enough to support heavy loads without bending or breaking.

Wheel:

- Type: Can be a single wheel or dual wheels.

- Material: The tire is typically made from rubber, while the wheel itself may be metal or plastic.

- Function: Allows for mobility and ease of transport.

- Features: Pneumatic (air-filled) tires offer better shock absorption and smoother movement, while solid rubber tires are puncture-resistant and low-maintenance.

Handles:

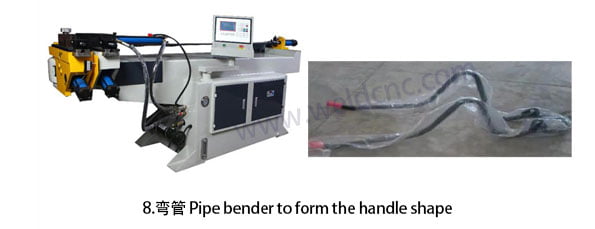

- Material: Commonly made from wood, metal, or plastic.

- Function: Used to push, pull, and control the wheelbarrow.

- Features: Ergonomically designed for comfort and ease of use, often with non-slip grips for better control.

Legs/Stands:

- Material: Generally made from metal.

- Function: Provide stable support when the wheelbarrow is stationary, keeping it level and preventing it from tipping over.

- Features: Positioned to ensure balance and stability under load.

Axle:

- Material: Made from metal.

- Function: Connects the wheel(s) to the frame and allows for smooth rotation.

- Features: Needs to be strong and durable to withstand the load and constant movement.

Understanding the structure of the trolley allows us to know what kind of machine is needed for each structure and to understand the construction of its production line

How to manufacture a wheelbarrow?

Production process of wheelbarrow production line

1. Design and Planning

- Concept Design: Create detailed designs and specifications, including dimensions, materials, and load capacity.

- Prototyping: Build a prototype to test the design, making adjustments as needed for functionality and efficiency.

2. Material Selection

- Steel/Aluminum: For the tray and frame, providing strength and durability.

- Rubber/Plastic: For the wheel and handles, offering resilience and comfort.

3. Cutting and Shaping

- Sheet Metal Cutting: Use laser cutting machines to cut metal sheets into the required shapes for the tray and frame.

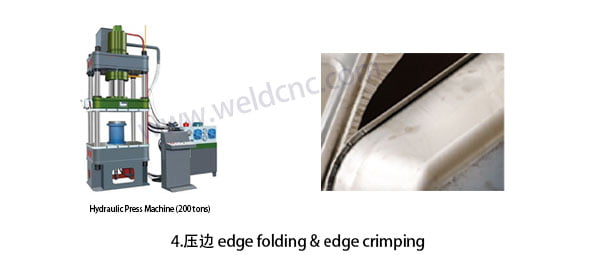

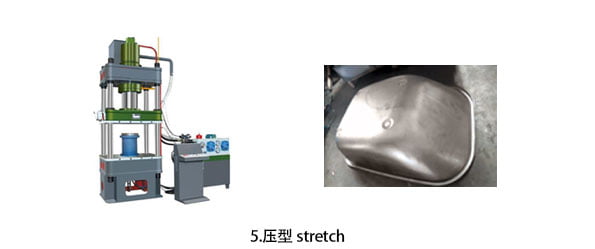

- Forming and Bending: Utilize press brakes and bending machines to shape the metal into the tray, ensuring it has the necessary depth and angles.

4. Welding and Assembly

- Tray Assembly: Weld the edges of the cut and formed metal sheets to create the tray. Ensure the welds are strong and smooth to prevent leaks or breaks.

- Frame Construction: Weld together the metal pieces for the frame, including the supports for the wheel and handles.

- Component Integration: Attach the tray to the frame securely using bolts or additional welding.

5. Surface Treatment

- Cleaning: Clean all metal parts to remove any oils, rust, or contaminants.

- Coating: Apply anti-corrosion coatings, such as powder coating or paint, to protect the metal from rust and environmental damage.

6. Wheel and Axle Installation

- Wheel Assembly: Attach the rubber or plastic tire to the wheel hub.

- Axle Installation: Insert the metal axle through the wheel hub and secure it to the frame. Ensure the wheel rotates smoothly and is firmly attached.

7. Handle and Leg Attachment

- Handle Installation: Attach the handles to the frame, ensuring they are ergonomically positioned and securely fastened.

- Leg Attachment: Attach the legs or stands to the frame to provide stability when the wheelbarrow is stationary.

8. Quality Control

- Inspection: Conduct thorough inspections of each component and the assembled wheelbarrow. Check for structural integrity, proper assembly, and smooth operation.

- Testing: Perform load testing to ensure the wheelbarrow can handle its rated capacity without bending or breaking.

9. Packaging and Distribution

- Packaging: Package the finished wheelbarrows securely for transportation. Use protective materials to prevent damage during shipping.

- Distribution: Distribute the wheelbarrows to retailers, wholesalers, or directly to customers.

Wheelbarrows are versatile tools found in a wide range of industries and applications. Here are some of the key fields where wheelbarrows are commonly used:

Where You’ll Find Them in Use

Application Scenarios for Wheelbarrow Production Lines

1. Construction

- Material Transport: Used to move heavy materials such as concrete, bricks, and debris around construction sites.

- Site Clean-Up: Helps in collecting and removing waste materials and rubble.

- Tool Transport: Convenient for carrying tools and small equipment.

2. Agriculture

- Harvesting: Used to collect and transport crops from fields to storage or processing areas.

- Fertilizer and Soil Movement: Ideal for distributing fertilizers, soil, and compost.

- Animal Feed: Helps in transporting feed and bedding to livestock.

3. Gardening

- Planting: Used to carry soil, mulch, plants, and gardening tools.

- Maintenance: Essential for garden clean-up, including collecting leaves, weeds, and clippings.

- Landscaping: Helps in moving rocks, stones, and other landscaping materials.

4. Landscaping

- Hardscape Projects: Used to transport pavers, stones, and gravel.

- Softscape Projects: Ideal for moving soil, compost, and plants.

- Construction: Helps in the construction of garden structures like patios and walkways.

5. Mining

- Ore Transport: Used to move ore, rocks, and minerals within mines.

- Waste Removal: Helps in the removal of waste materials from mining sites.

- Tool Transport: Convenient for carrying mining tools and equipment.

6. Warehousing and Distribution

- Goods Transport: Assists in moving goods and products within warehouses.

- Inventory Management: Helps in organizing and transporting inventory items.

- Loading and Unloading: Useful for moving items to and from storage racks and delivery vehicles.

7. Equestrian Facilities

- Stable Management: Used to transport hay, feed, and bedding for horses.

- Waste Removal: Helps in the removal of manure and waste materials from stables.

8. Municipal Services

- Park Maintenance: Used for maintaining parks and recreational areas, including transporting tools and materials.

- Street Cleaning: Helps in collecting and transporting litter and debris.

- Community Gardens: Assists in the upkeep and maintenance of community garden spaces.

9. DIY and Home Improvement

- Renovation Projects: Used to transport materials like tiles, bricks, and timber.

- Yard Work: Ideal for moving soil, plants, and garden waste.

- Repairs: Helps in carrying tools and repair materials around the home.

Following our discussion on traditional wheelbarrows, it’s time to delve into their modern counterpart: the electric wheelbarrow. The electric wheelbarrow represents a significant innovation, integrating advanced technology to greatly enhance operational efficiency and ease of use. This article will introduce the features, applications, and advantages of electric wheelbarrows, continuing from our previous exploration of traditional models.

Features of the Electric Wheelbarrow

1. Electric Drive System

- Power Source: Equipped with a high-efficiency electric motor, typically powered by rechargeable batteries.

- Ease of Operation: Speed and direction are easily adjusted via control buttons or a touchscreen on the handle.

- Battery Life: High-capacity batteries support extended working hours and are easy to recharge.

2. Enhanced Load Capacity

- High Load-Bearing: The electric drive system allows the wheelbarrow to carry heavier loads with less effort than manual models.

- Sturdy Construction: Made from high-quality materials to ensure stability and durability under heavy loads.

3. Ergonomic Design

- Comfortable Handles: Ergonomically designed handles reduce fatigue during prolonged use.

- Shock Absorption: Wheels and frame are designed with shock absorption features for smooth movement over rough terrain.

4. Versatility

- All-Terrain Capability: Suitable for various terrains, including flat surfaces, grass, dirt, and gravel.

- Multi-Functional Attachments: Can be equipped with detachable trays, tool racks, and other accessories to meet diverse needs.

When upgrading from a traditional manual wheelbarrow to an electric wheelbarrow, several additional steps and components are introduced into the production process. These steps ensure that the electric wheelbarrow operates efficiently and safely while harnessing the benefits of modern technology.

Additional Steps for Electric Wheelbarrow Production

1. Electric Component Design and Integration

- Electrical Design: Design the electric drive system, including motor, battery, and control circuitry.

- Integration Planning: Plan how to integrate these components into the existing wheelbarrow design.

2. Sourcing Electrical Components

- Motor and Battery: Source high-efficiency electric motors and rechargeable batteries.

- Control Systems: Obtain control units, sensors, and wiring harnesses.

3. Additional Cutting and Shaping

- Component Housing: Fabricate housing for the motor, battery, and control systems, ensuring protection and accessibility.

4. Electrical Assembly

- Motor Installation: Securely mount the electric motor to the frame.

- Battery Mounting: Install the battery in a protected compartment, ensuring easy access for recharging.

- Wiring and Connections: Connect the motor, battery, and control unit using durable, insulated wiring.

5. Control System Integration

- Control Unit Installation: Mount the control unit on the handles or a dedicated control panel.

- User Interface: Install buttons, switches, or touchscreens for user control of speed and direction.

6. Testing and Calibration

- Electrical Testing: Test the electrical components for proper operation, including motor function, battery life, and control responsiveness.

- Load Testing: Ensure that the electric wheelbarrow can handle the specified load capacity without performance degradation.

7. Safety Features Implementation

- Braking System: Install a reliable braking system to ensure safe operation.

- Overload Protection: Implement systems to prevent overloading and overheating of the motor and battery.

- Waterproofing: Ensure that all electrical components are adequately protected against water and dust.

8. Final Quality Control

- Comprehensive Testing: Perform extensive tests to ensure both the mechanical and electrical systems work seamlessly together.

- User Safety Checks: Verify all safety features function correctly.

9. Enhanced Packaging and Distribution

- Packaging for Electronics: Ensure the packaging protects the electric components during transit.

- Instruction Manuals: Include detailed user manuals covering operation, charging, and maintenance of the electric components.

The electric wheelbarrow is an upgraded version of the traditional wheelbarrow, combining the convenience of modern technology with high efficiency. Widely used across various industries, it significantly boosts productivity and reduces physical labor. For businesses and individuals with transport needs, the electric wheelbarrow is an ideal solution.

To learn more about our electric wheelbarrows or to get customized solutions, feel free to contact JY. Send us your inquiries today and let us help you enhance your operational efficiency and product quality!

FAQ About Wheelbarrow Production Lines

Wheelbarrows are commonly constructed using materials like steel, aluminum, or heavy-duty plastics for durability and strength.

Our wheelbarrows are designed for robustness, capable of withstanding heavy loads and tough working conditions.

Yes, we offer customization options to tailor wheelbarrow designs according to specific client requirements.

Our wheelbarrows include features such as ergonomic handles, stable frames, and in some models, safety brakes for secure operation.

Our production line is capable of meeting both small-scale and large-scale orders, ensuring timely delivery.

We adhere to stringent quality control measures throughout the manufacturing process, including rigorous testing of materials and finished products.

Routine maintenance typically involves checking tire pressure, lubricating moving parts, and inspecting for any signs of wear and tear.

Depending on usage and maintenance, our wheelbarrows are designed to have a long lifespan, providing years of reliable service.

Yes, we offer warranty coverage and comprehensive after-sales support to ensure customer satisfaction.

We have served a diverse range of clients across industries such as construction, agriculture, and landscaping, providing tailored wheelbarrow solutions.