Perforated metal sheets are essential in various industries, from architecture to automotive manufacturing. But how are these intricate sheets produced? The Perforated Sheet Production Line is the key to transforming raw materials into expertly designed perforated sheets. Let’s walk through the process of perforating sheet metal and explore the advanced machinery that makes it all possible.

The Perforation Process: Step by Step

Perforating sheet metal involves several precise steps that work together to punch holes into metal sheets, creating unique patterns, designs, or functional openings. Here’s how the process unfolds:

- Start with Material Preparation: First, the process begins by selecting the right material, whether it’s iron, stainless steel, copper, aluminum, or non-metallic options like plastic or fiber plates. Next, the material undergoes decoiling and leveling to ensure a flat surface, perfectly prepared for the next steps.

- Move to CNC Punching: Once the material is ready, our CNC-controlled perforated metal punching machine takes over. This machine excels at creating various hole shapes—such as round, square, and triangular—with remarkable precision. The machine ensures each hole is punched with an accuracy of ±0.1mm, resulting in consistently high-quality sheets.

- Customize to Your Needs: After setting up the machine, customization is easy. The CNC controls allow for quick adjustments, making it simple to produce anything from standard round holes to more complex diamond or decorative patterns, all tailored to meet specific project requirements.

- Finish with Precision: Finally, after the perforation is complete, the sheet may go through additional processes such as shearing, leveling, or slitting. These finishing touches ensure that the final product meets the exact specifications for its intended application.

Why Choose Our Perforated Sheet Production Line?

Choosing our perforated sheet production line means opting for versatility, precision, and comprehensive solutions that cater to a wide array of materials and configurations. Whether your operations are based in Chile, Qatar, Saudi Arabia, Brazil, or another region, our machines deliver reliable performance and exceptional results. Here’s why our production line stands out:

- Versatile Material Handling: Our machines effectively process both metallic (iron, stainless steel, aluminum, galvanized) and non-metallic (fiber plates, plastic) materials.

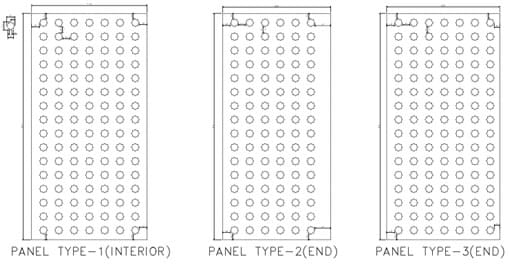

- Diverse Hole Patterns: The equipment can produce a wide range of hole patterns, including round, square, hexagonal, and cross-shaped designs.

- Unmatched Precision: CNC controls ensure each perforation is executed with pinpoint accuracy, maintaining a repetition accuracy of ±0.1mm.

- Complete Production Solutions: We offer a full range of machinery, from punching presses and decoilers to levelers, slitting machines, and shearing devices, providing a comprehensive solution for all your production needs.

Explore Our Machine Capabilities:

- Ample Working Space: Our machines accommodate sheets up to 1250mm x 2500mm.

- Material Thickness: Capable of processing materials up to 6mm thick.

- Power Efficiency: The main machinery operates with 3.0KW power, supported by a 30KVA power source.

- Flexible Options: Choose from punch and roller width options of 1000mm, 1250mm, or 1500mm.

- Custom Perforation: Maximum pitch of 20mm, with various tool sets available for different perforation patterns.

Regional Expertise and Applications

We design our machines to meet regional requirements, ensuring they are well-suited for markets worldwide. For instance:

- Saudi Arabia: Our machines can handle mild steel plates ranging from 3mm to 8mm thick, with hole diameters from 2mm to 30mm.

- Brazil: We offer equipment tailored for galvanized sheets, processing materials between 0.5mm and 1.2mm thick, with a 3mm hole diameter and a 5mm pitch. The machine easily processes sheets up to 1250mm wide and 2500mm long.

No matter where you are, our machines are adaptable, reliable, and ready to meet your production challenges.

Ready to Elevate Your Perforated Sheet Production Line?

Investing in our high-quality perforated sheet production line will enhance your manufacturing efficiency and product quality. Whether you’re setting up a new facility or upgrading existing equipment, we’re here to help you every step of the way.

Get in touch with Mr. Liu, our manager, to discuss how we can meet your specific needs:

- Phone/WhatsApp/WeChat: +86 13394110095

- Email: liu@weldcnc.com

Don’t wait—reach out today and discover how our perforated sheet production solutions can benefit your business.